Dynacode II – Package Printing

With the established Dynacode series, we set new standards for the printing of foil packaging. The keyword here is flexibility: mode, speed, print resolution, installation position — there are no limits regarding the wishes and needs of our customers.

The new product line Dynacode II is nothing other than the logical continuation of a success story. Below we will show you all operating modes and product components of the system.

Continuous mode

When printing continuously the printhead stands still while the packaging foil is guided through. Printing takes place during the operation of packaging machine.

Intermittent mode

When printing intermittently the printhead moves over the foil in order to move back to initial position. Printing takes place while the machine is at a short standstill, frequently while packaging is being filled.

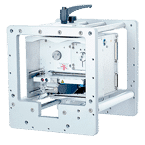

Control Unit

The control unit of the Dynacode II features an intuitive user interface with icon buttons and a 7“ colour touch-screen display with preview for verifying the layout. This makes it very easy to keep control over the print configuration.

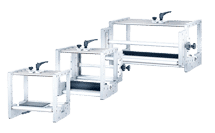

Bracket Systems

Our bracket systems permit an uncomplicated integration in your packaging line. The newly positioned return pulleys and the registration unit which can be mounted on all sides, offer a broad scope of variation of the foil run.

Left and reight Version

Again for Dynacode II we offer the bracket systems as a left-mounted and right-mounted variant. Horizontal and vertical mounting is virtually unlimited: maximum flexibility.

High-quality marking at low operating costs

By using transfer ribbons with a length of up to 900 m, the dynacode allows for less frequent ribbon changes. The high ribbon capacity directly reduces operating costs.

In addition to standard optimization, Shift and Save Start optimization are also available for optimum transfer ribbon utilization. The optimisation enables the gap between the individual layouts to be reduced to up to 1 mm across the roll length. Overprinting is avoided and a constant high pressure quality is guaranteed. The automatic film-saving feature reduces downtime and allows even greater use of transfer belts.

IP Version

The splash-proof version offers additional protection in harsh production environments. The splash-proof Dynacode version is ideal for labelling hygienic products and in wet-cleaning production environments such as dairies or coffee houses.

Excellent flexibility

The Dynacode series offers the best flexibility to easily switch between intermittent and continuous printing. During continuous printing, the print head remains stationary while the packaging film underneath is fed through uninterruptedly.

Print speed and clock frequency

Due to the very light and precise printhead guidance, the dynacode achieves a high clock frequency in the intermittent and continuous versions. Furthermore, we compensate slight parallelism deviations of the counterpressure plate / counterpressure roller by means of a floating print head bearing. Marking of variable data, batch numbers, date and time in real time, we achieve this with our own special software, which allows extremely fast data preparation.